Production Technologies

Production Technologies & Automation Technologies

Our engineering services consist of two interconnected main processes: Production technologies and Automation technologies. We offer this service to our customers whose electric motor design phase has been completed or who have a ready-made motor design.

We provide professional support to our customers from the concept phase to the production phase of their projects as a whole or at all levels they need.

With our customer-oriented approach and technological infrastructure, we are preparing you for the future by adding value to your projects and increasing your competitiveness in global markets with digitalization integration.

INTEGRATION OF MES AND DIGITAL APPLICATIONS INTO PRODUCTION

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

MECHANICAL AND ELECTRICAL DESIGN AND MANUFACTURING CAPABILITY

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

SOFTWARE DEVELOPMENT, DATA ANALYSIS AND INDUSTRY 4.0 CAPABILITY

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

KNOW-HOW TRANSFER IN OUR WIDE INDUSTRIAL NETWORK WITH OUR SOLUTION PARTNERS

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

KNOW-HOW EXPERT IN ELECTRIC MOTOR MANUFACTURING PROCESSES

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

MODULAR, EASY TO INSTALL, CONFIGURABLE SYSTEM UNITS

-Production Technologies

-Automation Technologies

-Production Technologies

-Automation Technologies

INTEGRATION OF MES AND DIGITAL APPLICATIONS INTO PRODUCTION

MECHANICAL AND ELECTRICAL DESIGN AND MANUFACTURING CAPABILITY

SOFTWARE DEVELOPMENT, DATA ANALYSIS AND INDUSTRY 4.0 CAPABILITY

KNOW-HOW TRANSFER IN OUR WIDE INDUSTRIAL NETWORK WITH OUR SOLUTION PARTNERS

KNOW-HOW EXPERT IN ELECTRIC MOTOR MANUFACTURING PROCESSES

MODULAR, EASY TO INSTALL, CONFIGURABLE SYSTEM UNITS

- Production Technologies

- Automation Technologies

1

Detailed Product Analysis

2

Determination of Production Processes

3

Determination of the Production Concept

4

Process Planning

5

Process Design and Analysis

6

Prototype Process Production

7

Realization

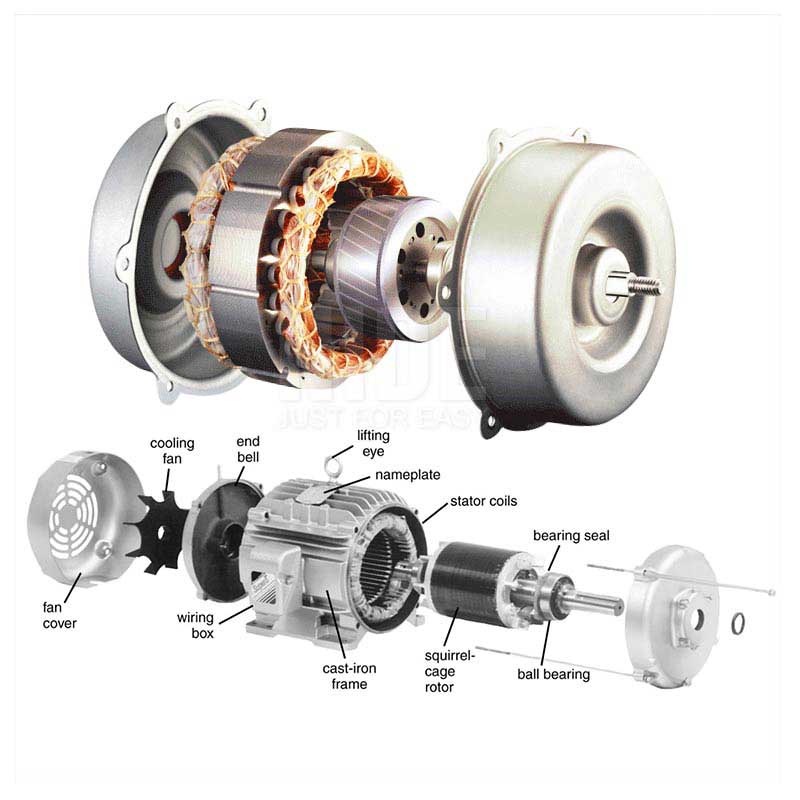

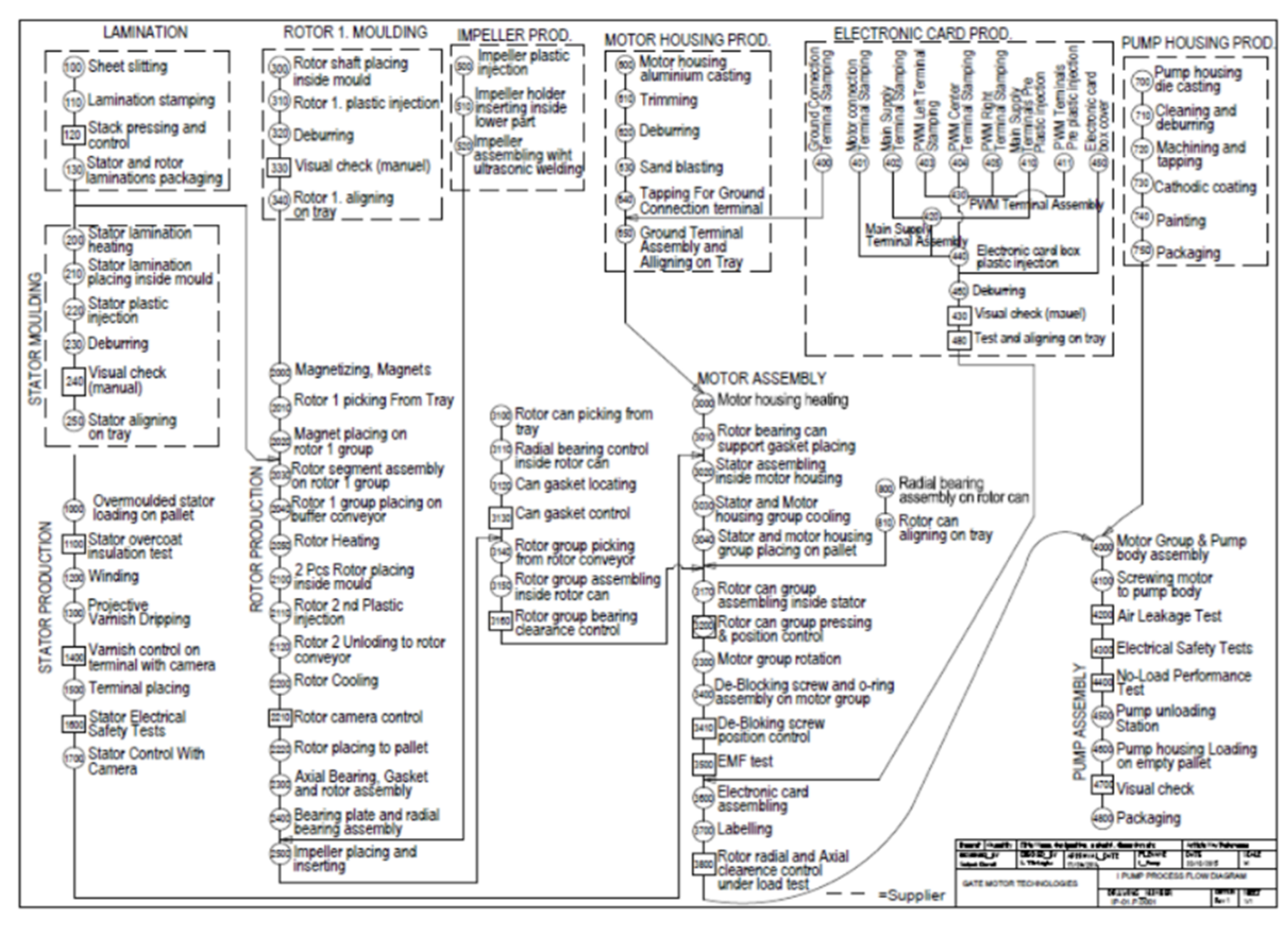

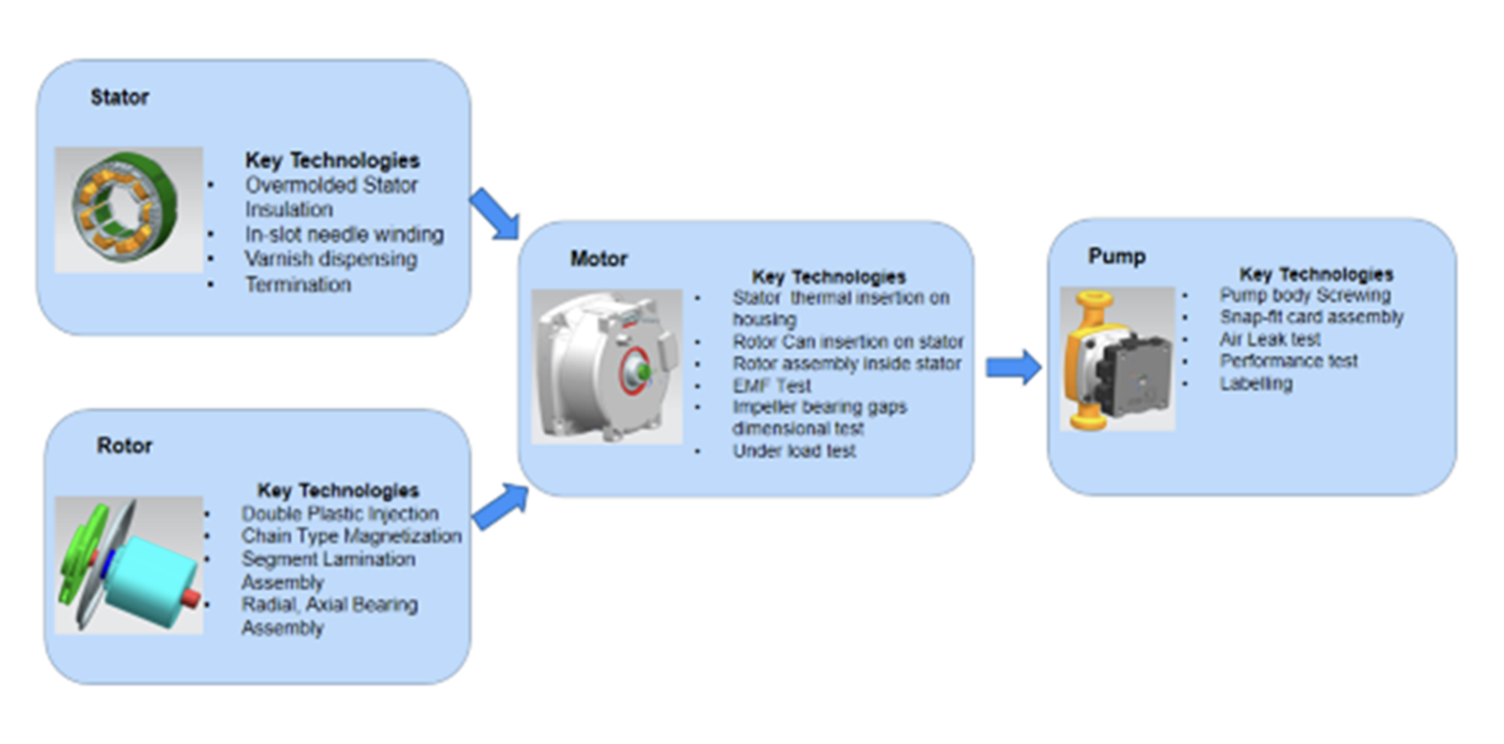

Production technology studies are the most important step in determining the infrastructure to be established for production. This study starts with a detailed analysis of the product. Product function, dimensions, tolerances, materials, product variety, etc. are evaluated in all aspects. Afterwards, the production processes are determined to be most suitable for the product and optimized in accordance of experience from similar processes. A production concept is created in accordance with customer needs, local production conditions and capacity needs. The process flow is created, process inputs and outputs are defined. In the design phase, it is evaluated whether the process is manual, automatic or semi-automatic. The equipment and key technologies are determined. Soft simulation of the process or, real simulations can be made with the same real part and planned equipment. The process design is optimized according to the simulation outputs. In addition, process FMEA studies are carried out according to the needs. After the completion of the process design, prototype product production is critical in equivalent process conditions. Open points for improvement, which are often detected in prototype process production, constitute important inputs to product and process design. Finally, the results obtained from the process studies are reported to provide input to the automation stage.

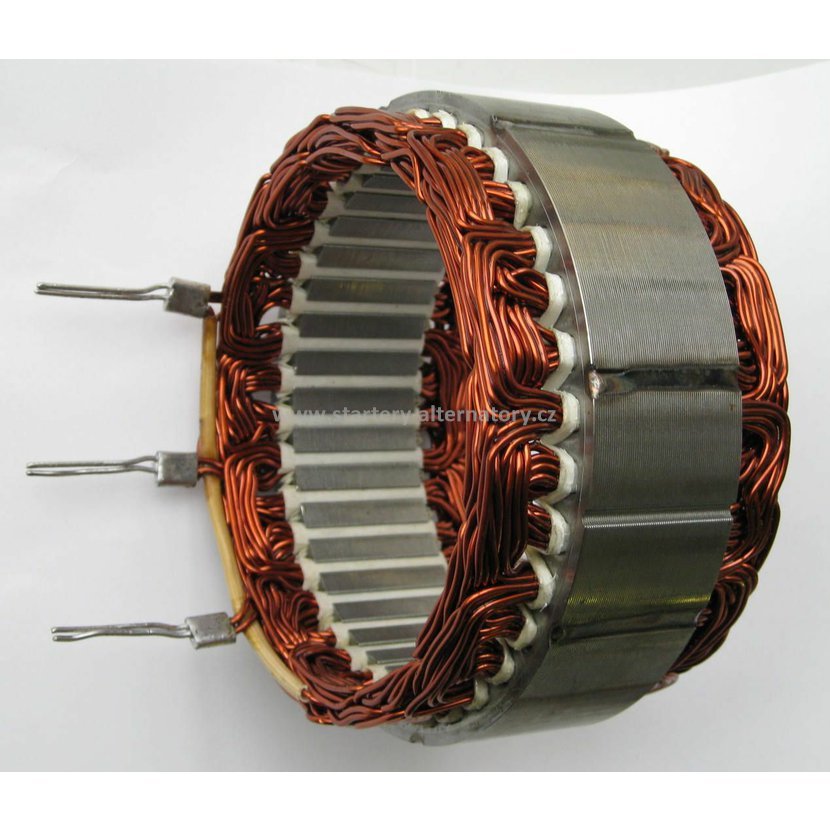

Lamination stacking & insulation

Assembly processes

Impregnation

Experinces on Electric Motor Production

Stator production & winding processes

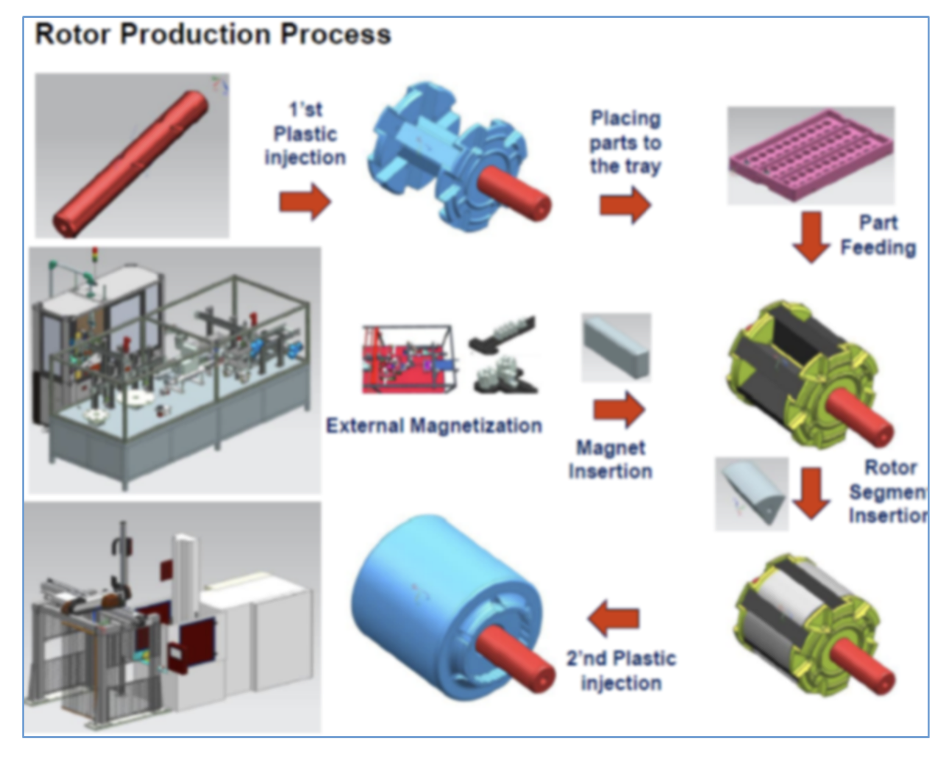

Rotor production

Molds, Toolings & Production equipments

Detailed Product Analysis

Determination of Production Processes

Determination of Production Concept

Process Planning

Process Design

Process Analysis (FMEA)

1

Process-Machinery Plan

2

Investment Planning

3

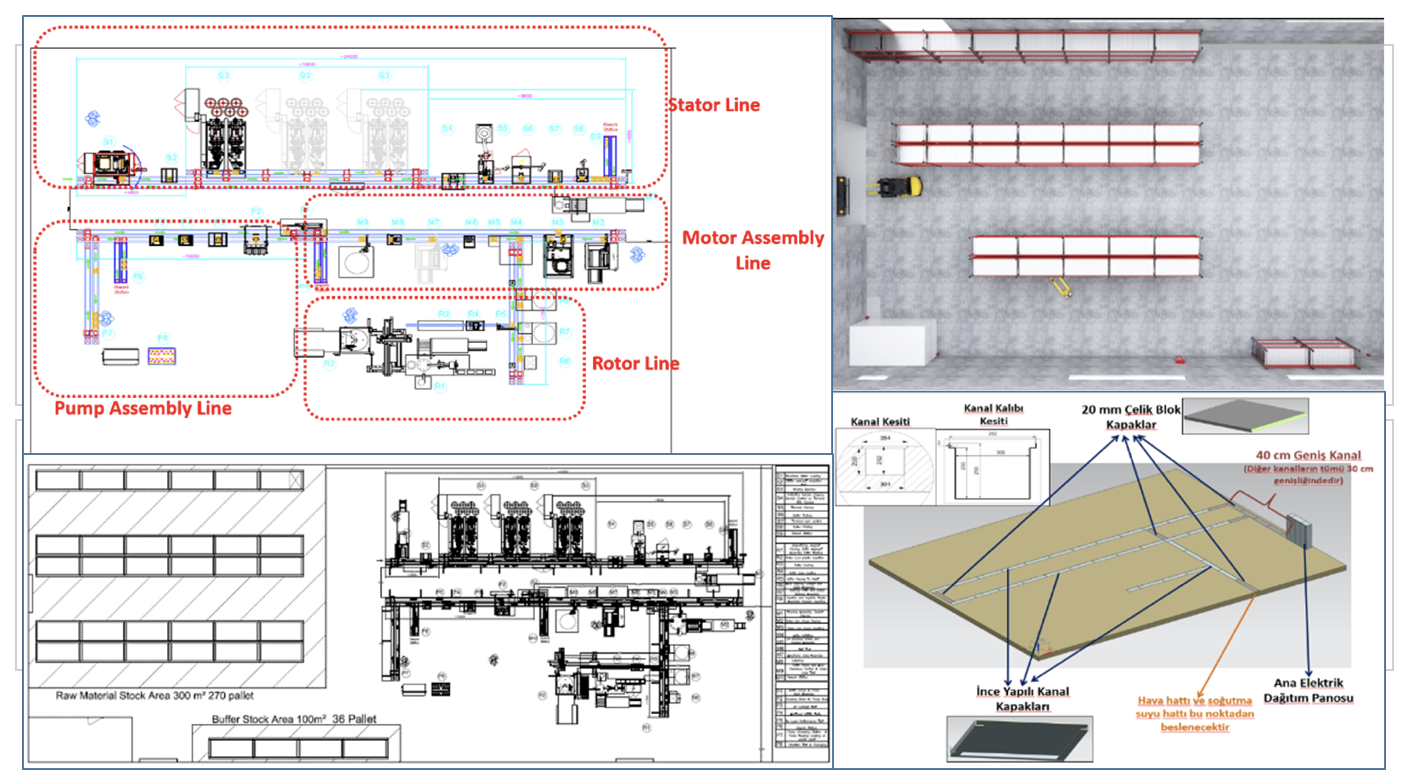

Layout, logistics and production infrastructure

4

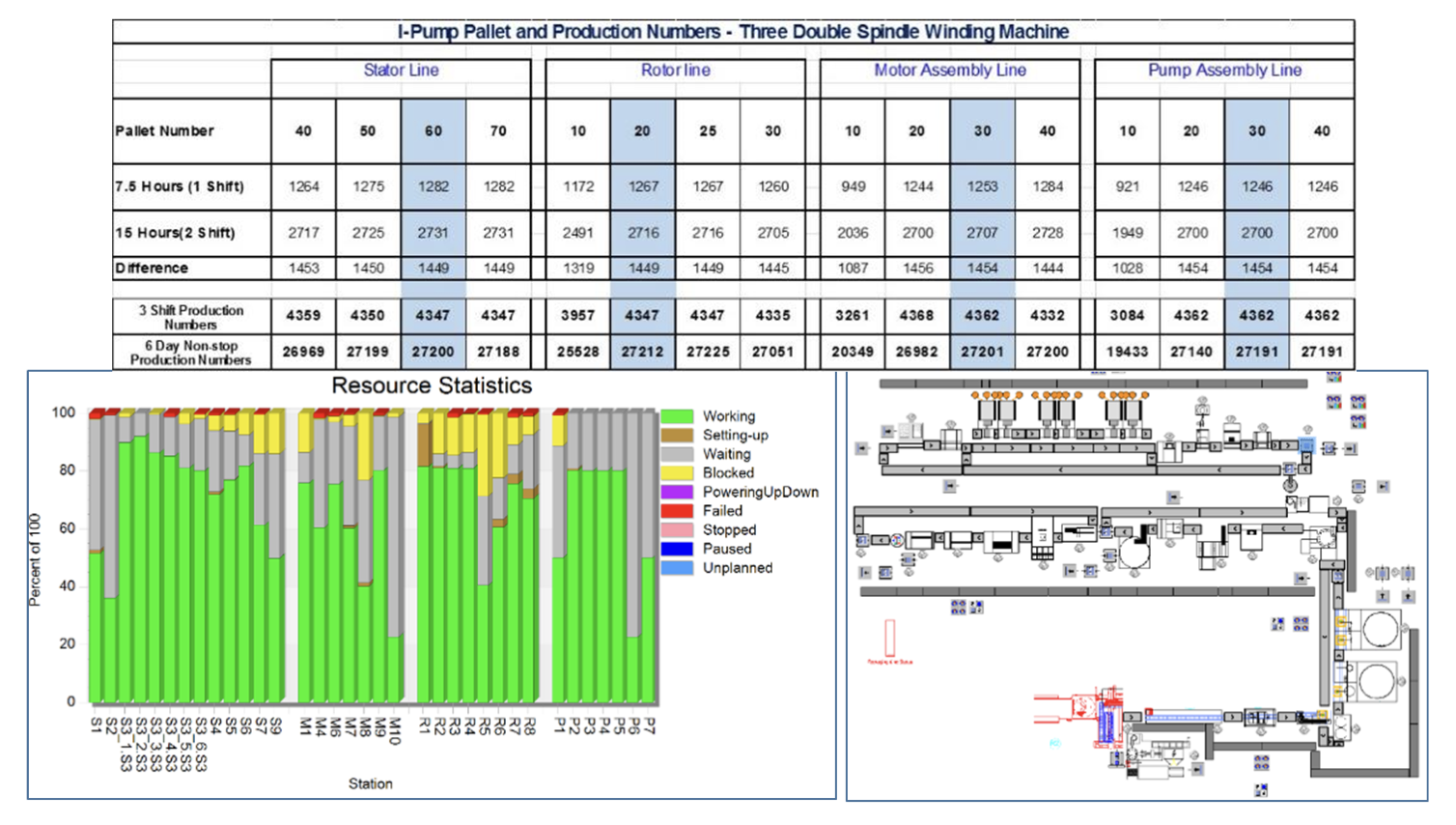

Simulation and Analysis

5

Conveyor and Pallet Design

6

Technical Specifications

7

Procurement or Internal Manufacturing

8

Realization

In projects whose production technology studies have been completed, automation studies are started. In the automation process, first of all, the process-machinery plan is prepared. This plan includes detailed information of all equipment to be used in the processes. A detailed investment plan is prepared for machinery and equipment. Layout, logistics and production infrastructure is created in order to fully meet the production needs of the automation to be made. These design outputs are analyzed with various analysis programs. Then, conveyor, line and pallet designs are made. Afterwards, the technical specifications of the machinery, equipment and test devices to be included in this production line are prepared. A detailed plan is prepared for the equipment to be manufactured in line with the investment plan and for the equipment to be outsourced. Purchasing and internal manufacturing processes begin. Manufacturing processes are divided into equipment-based subgroups and followed up with detailed project plans. In the realization phase, the completed equipment and machines are mounted on the previously prepared infrastructure and the commissioning works are started. When the entire production infrastructure is prepared, trial production is made and the final Acceptance process is started.

Process Machinery Plan

Investment Planning

Layout Logistics & Prod. Infrastructure

Simulation and Analysis

Conveyor and Pallet Design

Technical Specifications